Introduction. Contemporary contactless research methods of heterogeneous plasma provide the analysis of the laser radiation intensity scattered by a dispersed component different angles. Data processing of optoelectronic devices response of the measuring complex to a scattered light signal makes it possible to determine the scattering indicatrix (angular distribution of scattered radiation) and to determine such important parameters of the smoky plasma as the grains size distribution function of the condensed phase, as well as their concentration and spatial distribution [1]. It is assumed that the time interval for measuring the parameters of the plasma medium is sufficient for the system to be considered quasi-stationary.

In recent decades, after the publication of the first results on the formation of ordered spatial structures of particles in a smoke plasma [2] and a number of theoretical works, interest in such studies has grown significantly, which led to the experimental identification of "plasma crystals" in a gas discharge plasma with monodisperse condensed grains [3].

Nevertheless, interest in the properties of smoky plasma is growing due to its use in non-standard technological and power systems. It should also be noted that the effect of displacement of the ionization equilibrium in relation to the quasi-neutral plasma in smoky plasma is predicted, which has not yet received experimental confirmation. All this stimulates the development of methods and devices for the experimental research of heterogeneous smoky plasma.

Objective of the present work is development a technique for research of laser radiation scattering by the condensed grains of heterogeneous smoky plasma for detecting ordered spatial structures and creation of the automated experimental stand.

Statement of the problem. Following the above brief scientific literature review, it can be concluded that the spatial ordered structures of charged condensed grains in a gas-discharge plasma ("plasma crystals") have been researched in sufficient detail. Along with this, only some publications are devoted to the spatial structures of particles in smoky plasma, despite the fact that they were discovered much earlier.

The condensed phase in the smoky plasma is formed directly in the combustion products at a high temperature and therefore can contain three fractions of grains, with the smallest fraction having a size of about ten nanometers, as a result of which the use of optical methods has a number of restrictions. The same applies to grains of the second fraction – about a hundred nanometers. Thus, classical optical methods are applicable only for the third fraction of grains larger than a micron. Along with that, the results of calculations show the possibility of the formation of spatial structures of the micron fraction of grains, and therefore in this working we are focused on the coarse fraction. Consider the conditions for the appearance and possible registration of an ordered spatial structure of grains of a condensed phase of the "diffraction grating" type in smoky plasma.

The formation of the diffracted ray is based on the Bragg's law: 2LsinΘ = λ, where L is the distance between particles (step of the diffraction grating), Θ is the an-and it lies in the same plane with the incident and transmitted rays, and its so-called “exit angle” from the grating is equal to the angle of the incident ray Θ. When monochromatic rays with different directions enter the volumetric grating, only that diffracted ray will be observed, the propagation direction of which satisfies the Bragg's law. This property, called "angular selectivity", is largely determined by the relative thickness of the grating, expressed as the ratio of the geometric "thickness" to the grating step h/L. The larger this value, the pointed is the grating selectivity.

In addition, as it follows from [4], that the intensity of the diffracted ray I is proportional to the square of the number of those elements of the grating N that are within the volume V of the intersection of the incident laser beam with the diffraction grating, i.e. I ~ N. In the technique of optical measurements of dispersed systems, such a volume V is called "counting volume". Its value for installations that measure the spatial distribution of light energy I reflected from a collection of grains (or one grain) located at a given time in the "counting volume" is determined by the diameter of the laser beam D and the aperture φ of the photodetector. In the first approximation, the “thickness” of the grating is h ≈ D, and the value of D depends on V. For more reliable recording of the diffracted ray (i.e., increasing I), V should be increased due to the expansion of the aperture φ, which will lead to an increase in the number of grains N, participating in the scattering of light radiation.

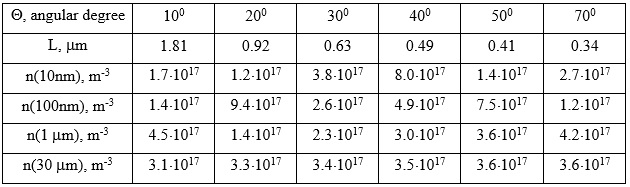

Let us calculate what the parameters of the dispersed system should be, namely – the distance between grains (grating constant) L and the numerical concentration grains n for four fractions, which are observed in experiments with dimensions: 10 nm, 100 nm, 1 μm and 30 μm. The grating constant L is determined as L = λ/ 2sinΘ = 0.63/2 sinΘ at wavelength of the "red" laser λR = 0.63 μm and various fixed viewing angles Θ.

The calculation results for L and n are shown in Table 1.

Table 1. Values of grating values L and grains concentration n at different scattering angles of the model diffraction grating Θ

As can be seen from Table 1, for detect the diffracted ray, the grating constant L should be about a micron (from 1.8 μm to 0.34 μm), and this value depends on the observation angle Θ (the larger it is, the denser the grating). The dependence of the grains concentration n from Θ is the more significant, then smaller the grains size. So for a fraction of 10 nm, the difference in n takes place by two orders of magnitude (from 1.7・1017 m-3 at Θ = 10° to 2.7・1019 m-3 at Θ = 70°). The numerical concentration n of the 30 μm fraction is already practically independent of Θ. From these calculations the conclusion follows, that the detection of the "plasma crystal" in the condensed phase is a unique only by contemporary experimental methods.

Description of the experimental stand. Scattered radiation is recorded in the angular sector from 00 to 70°.

The removable compartment contains three laser emitters with wavelengths λIR = 808 nm, λR = 630 nm and λG = 532 nm. The stand consists of a fixed base, on which a table with photodetectors is installed with the help of racks. On the surface of the table there are eight lenses of photodetectors, which are attached to the table with one clamping screw on the racks, which makes it easy to direct the optical axis of each of the lenses towards the center of rotation of the fixed base of the experimental stand.

On the movable arm, which can rotate in a circular arc around the center of the fixed base, a table of laser emitters is installed with the help of two racks at the required height on which a generator for the formation of a pulsed pumping current of laser diodes and a removable compartment for attaching these laser diodes. The movable arm can be fixed in any required angular position, which allows you to change the orientation of the laser beam relative to the photodetectors, thereby investigating the scattering indicatrix in any angular coordinates with the angular width of the zone 700.

When the stand is fully ready for the experiment, the "Ready-Standby" mode is introduced until the flame of the torch for research appears in the working zone. The moment of appearance of a light flash is registered by a flame sensor, from which an automatic procedure for recorded and measuring the parameters of laser beam that has passed through the flame and/or is scattered from the grains of the plasma formation is started. During the first 0.5 second, the software automatically adjusts the dynamic range of the measurement level of the input optical signal in each measuring channel. The end-to-end sensitivity of each of the receiving channels is set, at which the average value of the received signal is equal to half of the entire measurement range. Then, within the next 2.5 seconds, the current values of the transmitted and/or scattered signals are recorded in each of the eight measuring channels with a frequency of 1000 measurements per second, that is, a total of 2500 measurements in each channel.

Experimental research. The combustion process was recorded on a video camera, the spectral range of "image capture" which extended into the infrared region. When a flame appeared, the photo-sensor triggered the electronic unit of the setup, which had been put into standby mode before the experiment. The first 0.5 seconds of burning were used to adjust the electronic unit to the signal levels from all photodetectors, and during the rest of the experiment (about 2.5 seconds), data was accumulated in the stand controller.

Then, after the end of the combustion process, the data from the controller were downloaded via the USB port for 3 seconds to the working computer of the stand. Computer processing of the information showed that in ≈ 2.1 seconds after the beginning of the combustion process, a significant splash of the intensity of radiation scattered from the particles of smoky plasma, recorded by the photodetectors of all seven channels, is visible.

In this case, the first channel, which records the attenuation of the main laser

beam as it passes through the flame, did not detect the burst curve, corresponding to a signal recorded at an angle of 10o relative to the main beam, has the highest amplitudes of laser radiation scattered by smoky plasma grains with a wavelength of λR = 630 nm. From the beginning of the combustion process +0.5 s) was about 1.2÷1.3 conventional units (determined by the process of electronic “splitting” signal). The amplitude of the splash of the signal was about 2.7 conventional units, which is almost 2 times more than the average value. Splashes of the same order were observed at other observation angles (by other photodetectors), but with a lower intensity. As noted above, the first photodetector on the "main" axis of the laser beam did not register any splashes of signal intensity.

One of the explanations for this effect can be the scattering of the laser beam on a volumetric diffraction grating consisting of grains of a condensed phase, such as a "dusty crystal", which emerged situationally in the plasma flow.

It should be noted that in experiments with a "red" laser (λR = 630 nm), a splash in the scattered radiation curves was observed only once. When using an infrared laser (λIR = 808 nm), the splash was not recorded. Most likely, this is due to the uniqueness of the event of the formation of dust crystals, which emphasizes the need for comprehensive researches of the properties of the smoky plasma formed in the combustion products of pyrotechnic compositions.

References:

1. Alden M. Spatially and temporary resolved laser/optical diagnostics of combustion processes: From fundamentals to practical applications. Proceedings of the combustion institute. 2023. V. 39(1). Pp. 1185-1228.

htps://doi.org/: 10.1016/j.proci.2022.06.020.

2. Vishnyakov V. I., Dragan G. S. Ordering spatial structures of dust grains in the thermal plasma. Physical Review E. 2006. V. 73(1-7). 026403. https://doi.org/10.1103/PhysRevE.73.026403

3. Hariprasad M.G., Bandyopadhyay P., Arora G., and Sen A. Experimental observation of a dusty plasma crystal in the cathode sheath of a DC glow discharge plasma. Physics of Plasmas. 2018. V. 25. 123704. https://doi.org.0.1063/1.5079682.

4. Vishnyakov V.I., Dragan G.S. Coupling parameter for the low-temperature plasma with condensed phase. Condensed Matter Physics. 2007. V.10(2). Pp.201-208.

|